High-potency products are increasingly becoming more important in the chemical world. The ability to manage these molecules is a result of the combination of the design of the production plant and specific operating procedures.

Delta, with the help of leading high-containment device suppliers, offers its customers a global approach, providing integrated solutions.

Process machines face high-containment issues when dry product is outside the main chamber. This usually happens during:

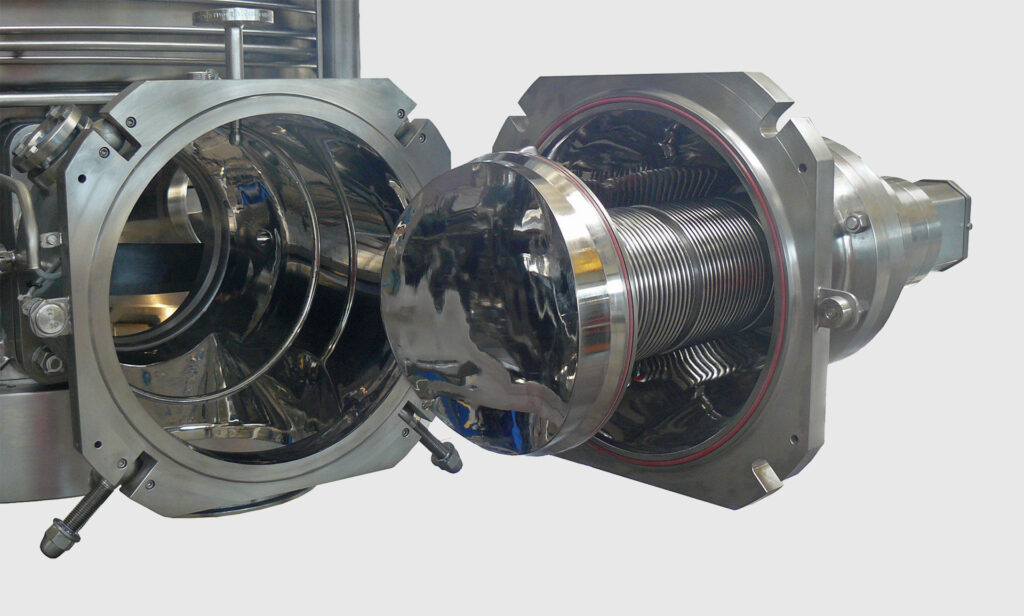

Delta offers specific solutions for containment issues for all our process machines, helping customers choose the correct approach based on the product, danger level, and operating procedures. Delta expertise can transform a simple process vessel to a process machine with high-containment features by (among others):